ADDITIVE MANUFACTURING 101

Metal Binder Jetting

What is Metal Binder Jetting?

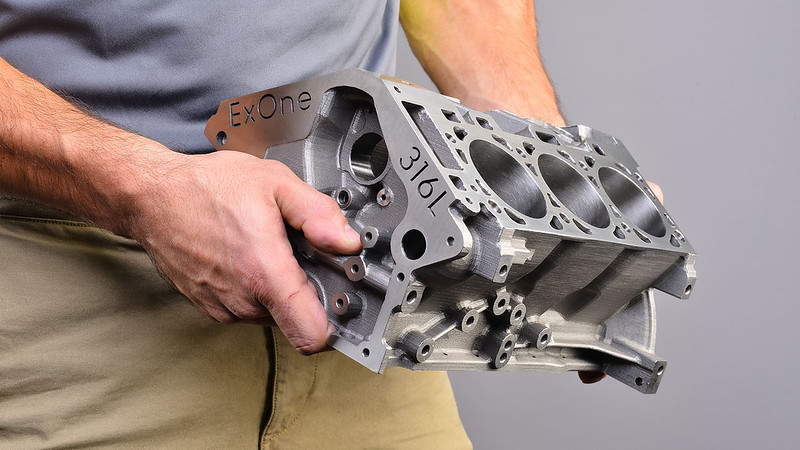

Metal Binder Jetting is an Additive Manufacturing process used to create functional metal parts with highly complex geometries.

Metal Binder Jetting Technology Characteristics

Many different types of materials can be used in metal binder jetting. DSB is exploring applications involving stainless steels, low alloy steels, specialty alloys, and reactive materials, among others.

Metal binder jetting is used to create designs with nearly limitless 3D complexity possibilities, including:

- Geometries not previously possible or economically feasible

- Greater complexity and better surface finish/feature details compared to investment casing designs

- Ability to combine multiple parts into one

- Geometries that are difficult to produce in hard tooling

- Labeling: part numbers, names, and logos

- Internal structures (cavities, channels, etc.)

- Internal undercuts

- Holes of any shape at angles to one another

- Minimum printed hole size: 1.5 mm

- Bracing structures to provide extra part strength

- Light weighting: only putting material where needed

- Support structures to help manage sintering shrinkage and distortion

Metal binder jetting can hold the dimensional precision of +/- 0.75% printed; +/- 1.0% sintered and a minimum wall thickness of 1.0 mm, depending on part geometry and green strength after printing. No tooling is required.

Click here for more information on our metal binder jetting products.

Understanding Metal Binder Jetting Technology

Design Features

Explore & learn more about Metal Binder Jetting design features and possibilities. A practical and functional 3D printing solution.

Prototyping

Explore & learn about Metal Binder Jetting prototype service. A 3D-print complex metal parts with nearly limitless design freedom.

Resources

Optimize your part design for Metal Binder Jetting with highly complex geometries, unique features, greater surface finish, and no tooling.