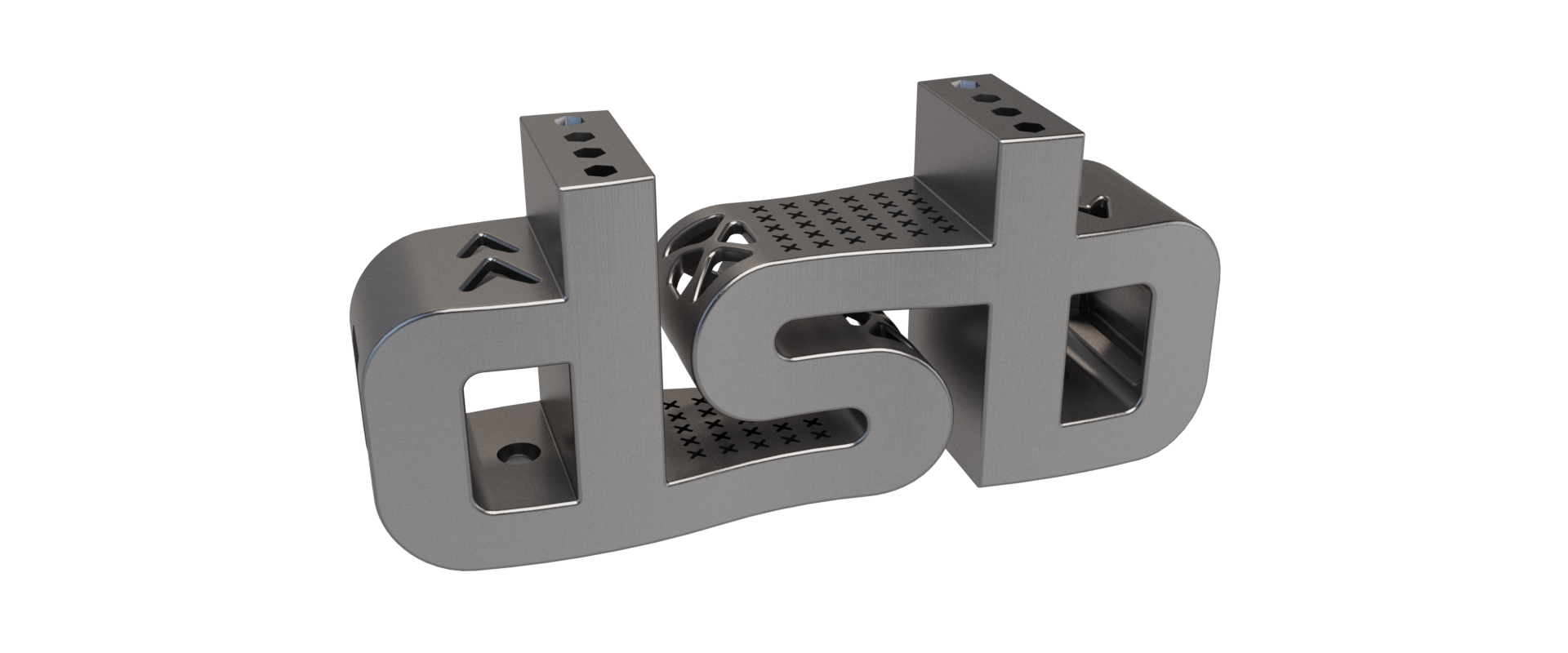

METAL BINDER JETTING

Explore the Design Possibilities

-

-

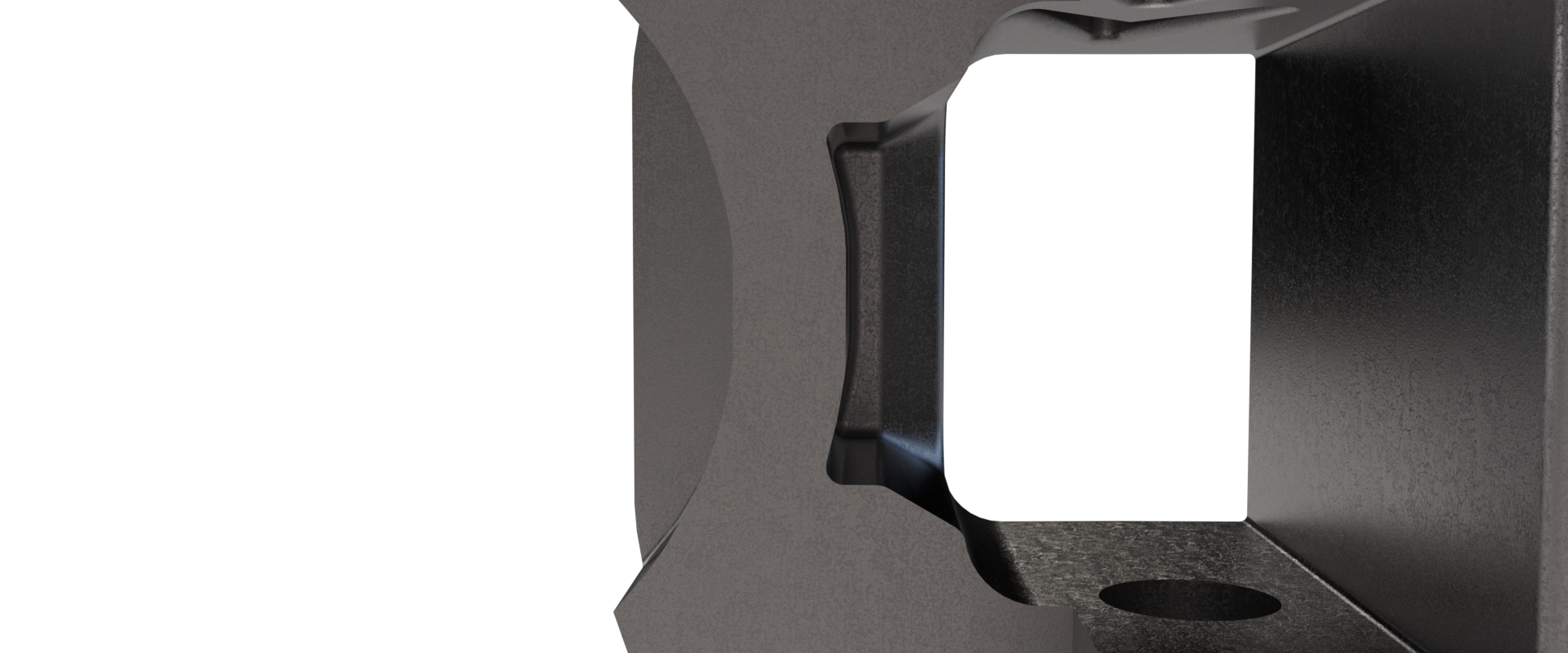

Face Curvature

The continuous curvatures on the front and back faces of the part resemble a wave-like design. Metal Binder Jetting (MBJ) can deliver both flat or curved surfaces without impacting the bottom line, whereas conventional manufacturing processes prefer flat faces only, due to the ability to datum off and use simpler machining methods.

-

Spiraled Hex

The top view of the part shows a series of hexes that cut all the way through the letter ‘D’ and letter ‘B’, which converge into the center of the part and spiral at a consistent rate of twist throughout. These design features would be impossible to duplicate using a conventional manufacturing process.

-

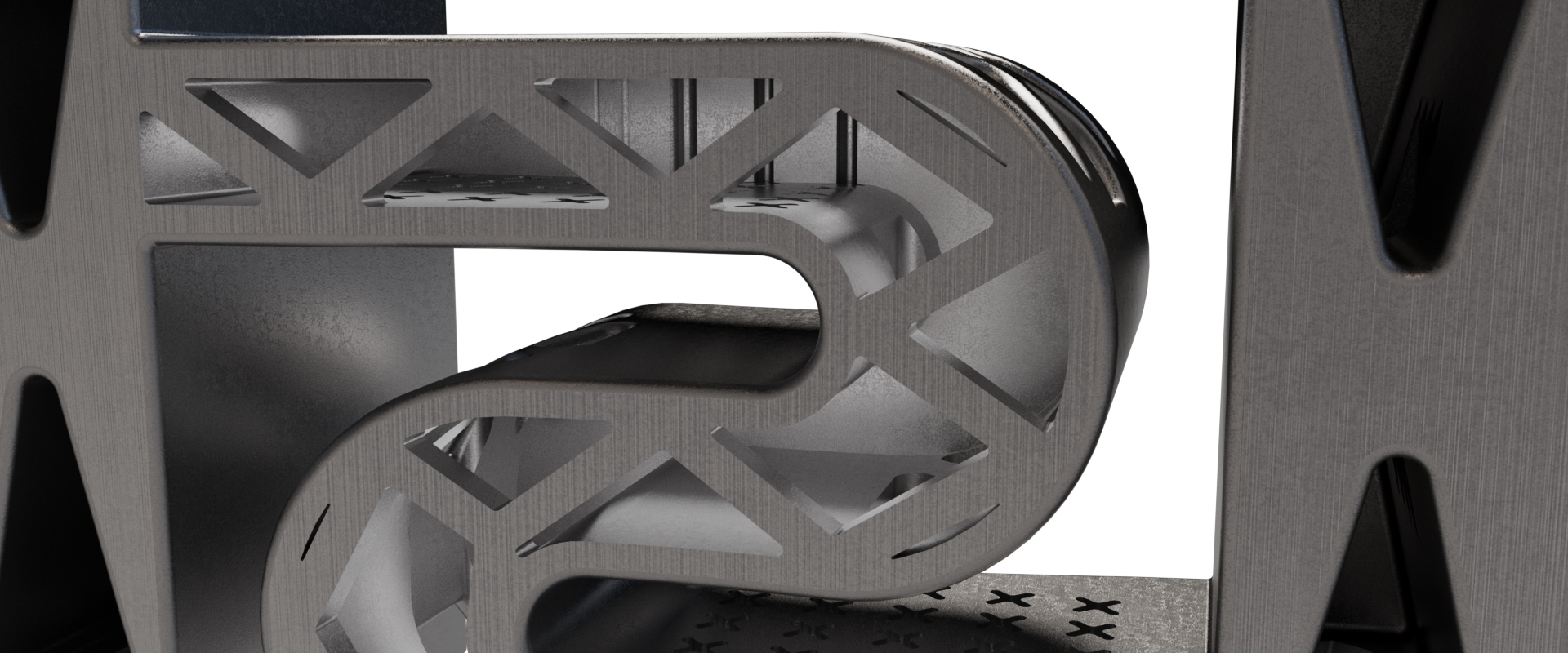

Triangles

Lightweight triangles are integrated within the curves of the ‘S’ and extend partially through the part. If one were to design a similar piece using a conventional manufacturing process, these features would add a great deal of operations to manufacture, thus increasing cost.

-

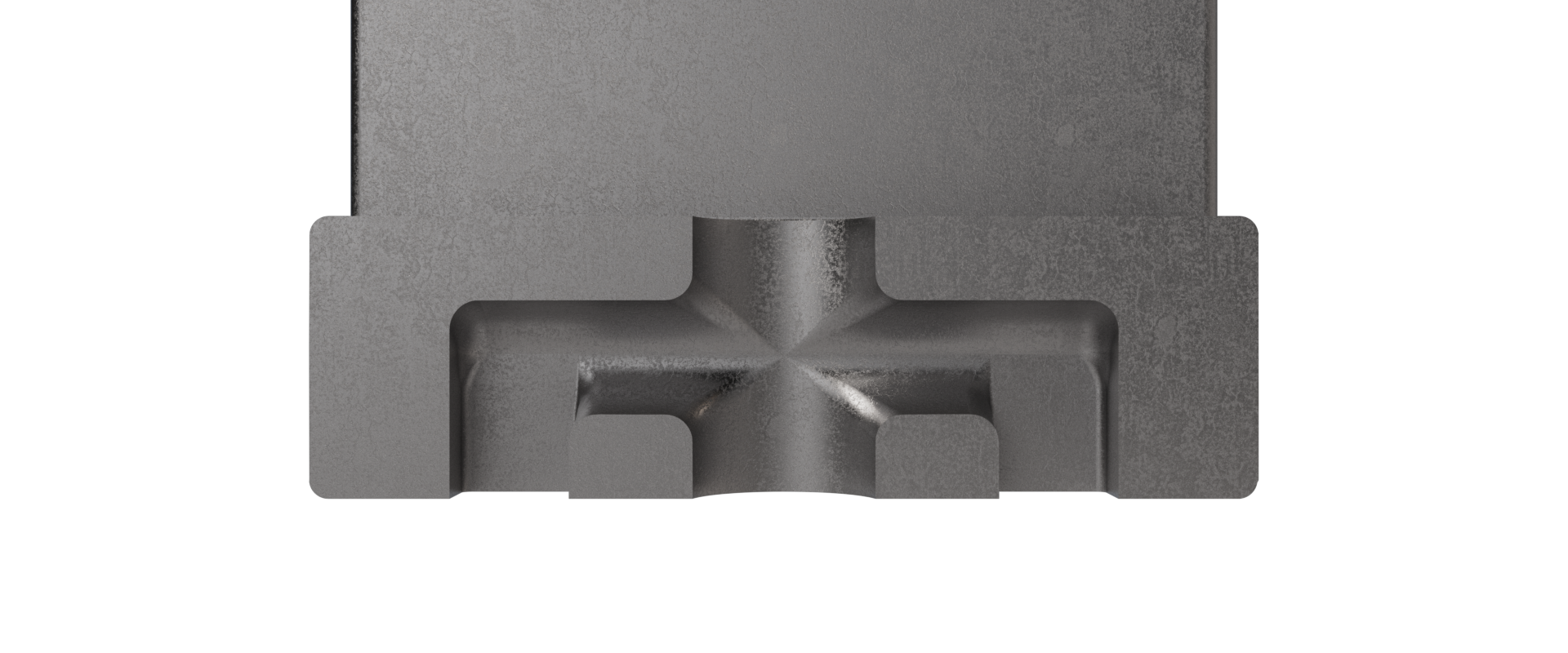

The “X”

The center of the part (Top and bottom view of the letter ‘S’) contains a series of thin ‘X’s, which do not extend all the way through the part. This is another capability that differentiates Metal Binder Jetting (MJB) from the conventional manufacturing process with traditionally unmanufacturable features.

-

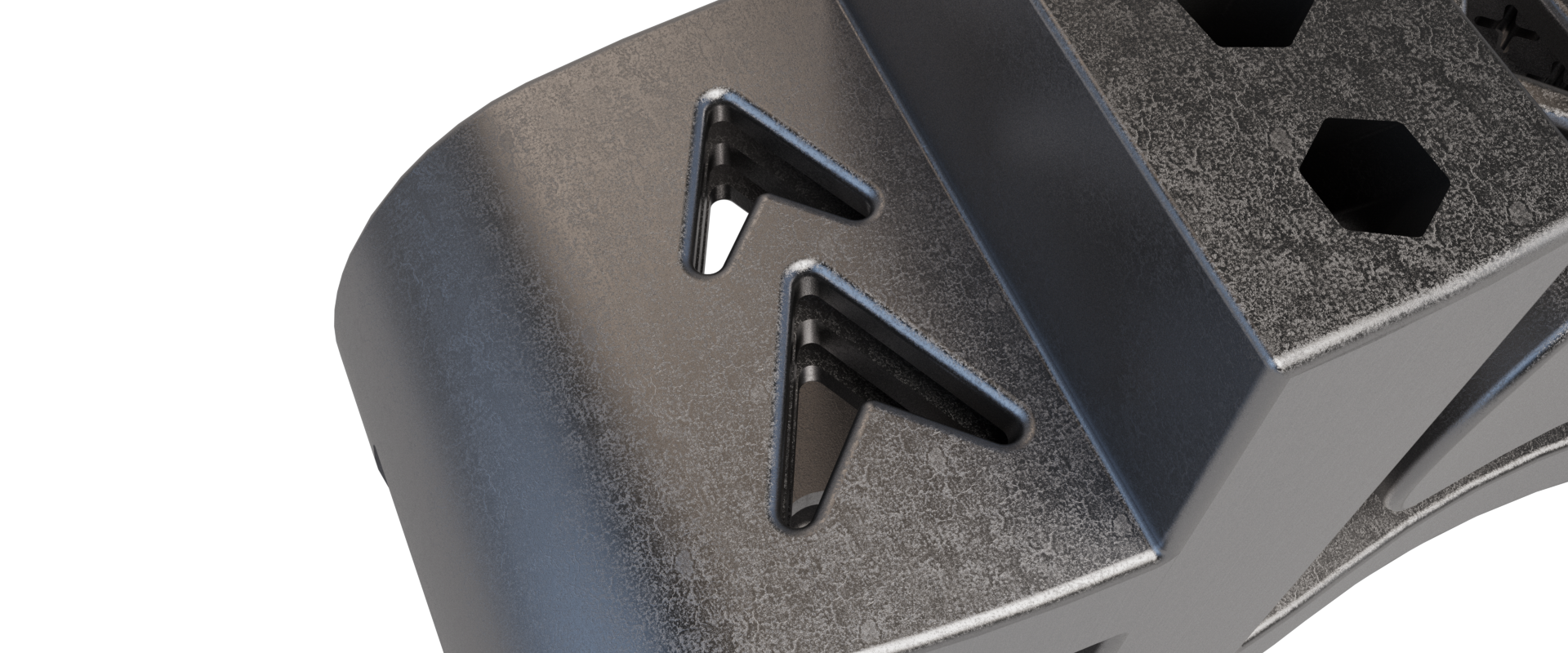

Tapered Arrows

Note the arrow(s) tapered in different directions at the top of the ‘D’ and ‘B’ of the part. Additional operations, and thus cost, would be required if designing these arrows in a conventional manufacturing method.

-

Pockets

The ‘D’ and ‘B’ have both rectangular and triangular lightweight pockets that partially extend through the part. These pocket features would require additional manufacturing operations to produce, making Metal Binder Jetting (MBJ) the unfailing choice for intricate and complex parts.

-

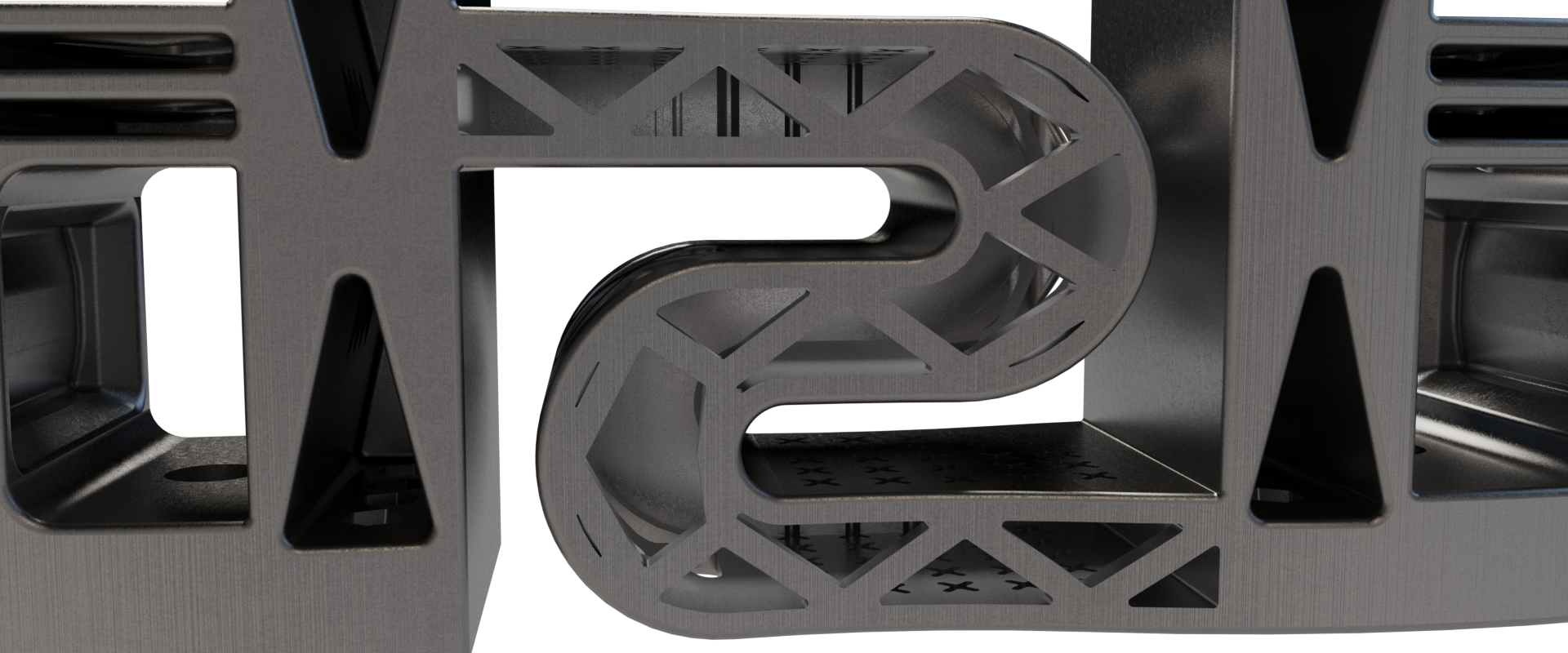

Shelling

The center ‘S’ in the part is shelled out, while maintaining a constant wall thickness throughout the part – including the curved surfaces. This feature would be unmanufacturable using a conventional manufacturing process.

-

Lattice Frame

The shelled ‘S’ is also designed with a lattice frame, which does not extend through the complete shell. This lattice design would be unmanufacturable using a conventional manufacturing process.

-

Cross-Section: Scalloped Features

Inside the ‘D’ and ‘B’, there are regions of scalloped material that have been removed. Between the scallops, there is a uniform wall thickness. These features would be costly to manufacture through a conventional manufacturing process, with the inner scalloped feature being nearly impossible to manufacture by conventional methods.

-

Cross-Section: Internal Channels

The bottom of the ‘D’ and ‘B’ shapes of the part are designed with internal channels that contain both oval- and rectangular-shaped channels, with portions of these channels that do not extend outside of the surface. This design feature would be unmanufacturable using conventional manufacturing methods.

Fast and production-ready 3D printing

Experience high-speed Additive Manufacturing with Metal Binder Jetting — a practical and functional 3D printing solution that offers both complexity and volume in production. With the largest binder jetting systems and infrastructure for industrialization, we enable the scale of production you need, when you need it.

Is Metal Binder Jetting the right solution for your project?

Understanding Metal Binder Jetting Technology

Prototyping

Explore & learn about Metal Binder Jetting prototype service. A 3D-print complex metal parts with nearly limitless design freedom.

What is it?

What is Metal Binder Jetting? Metal Binder Jetting is used to create designs with nearly limitless 3D possibilities.

On-Demand Webinar

In this Industrialized Metal Binder Jetting webinar, DSB’s Senior Additive Manufacturing Engineer Neil Belanus explores the relationship between a parts producer and their customer, including the manufacturer’s role as a knowledge provider.