Our Company History

We have been on the leading edge of new innovations for powder metal components for over 50 years. In 2022, our company name evolved and our drive for collaborating, discovering, and innovating only intensified.

1980: SSI Technologies is Formed

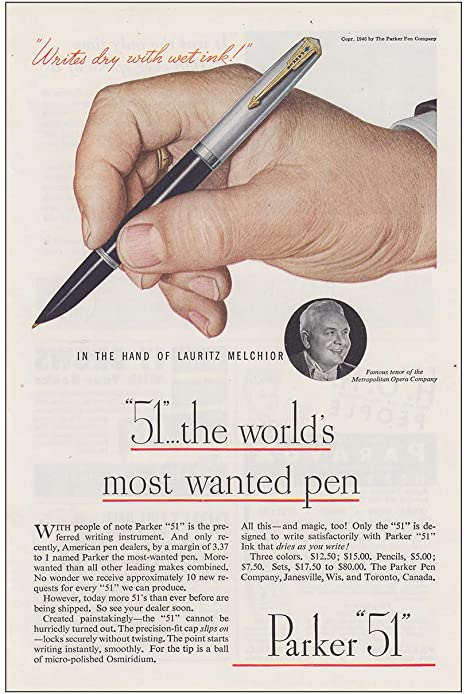

Parker Pen sells the sintering division to a private group of investors who re-name the company SSI Technologies, Inc. The company expands material and process offerings with the development of Full Density and Metal Injection Molding (MIM) product lines featuring stainless steel and tool steel materials. During this decade, SSI developed a line of tone wheel products to the support the emerging Anti Lock Brake industry.

Early 2000s: Leading the PM Industry

SSI strategically invested to expand their capabilities and become an industry leader in secondary machining. SSI earned TS 16949/ISO 9001 Quality Certification, ISO 14001 Environmental Certification and numerous supplier of the year awards. In support of rapid growth, SSI invested in two more building expansions as well as purchasing a second building in Janesville, WI to increase its total manufacturing square footage to a level of 150,000.

2010: Growing and Expanding

SSI invested in additional manufacturing equipment and building space, increasing their manufacturing square footage to its current level of 250,000. The company also expanded its global customer reach in five countries with the addition of two new product lines. SSI was honored by customers with multiple Supplier of the Year awards as production volumes grew beyond 100 million parts per year.

2022: Our Evolution to DSB Technologies

After becoming its stand-alone business in 2019, SSI grasped the opportunity to grow the business and leverage its core capabilities with new technology. To do this, the company name needed to be changed.

In May 2022, SSI Sintered Specialties formally changed its company name to DSB Technologies. Along with a rebranding, DSB announced the expansion of its forming technology portfolio to include Metal Binder Jetting, Metal Injection Molding, and CNC Press Technology.