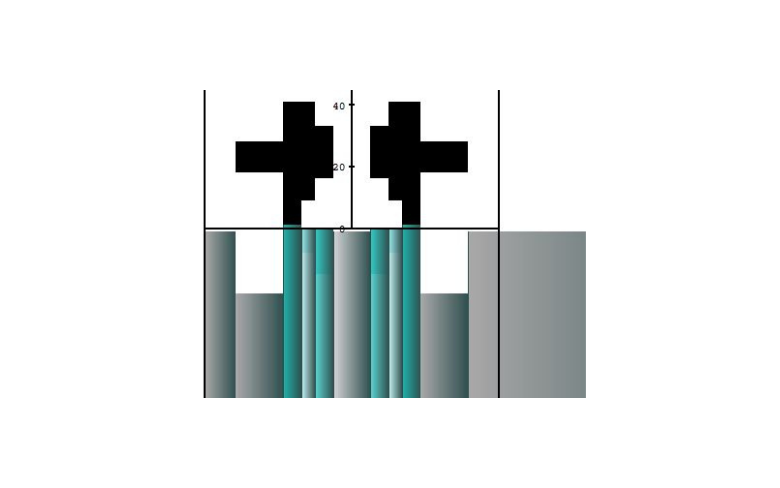

Step 2: Transfer

Press moves into Transfer Position to arrange the loose powder so that each level is consolidated at the same rate.

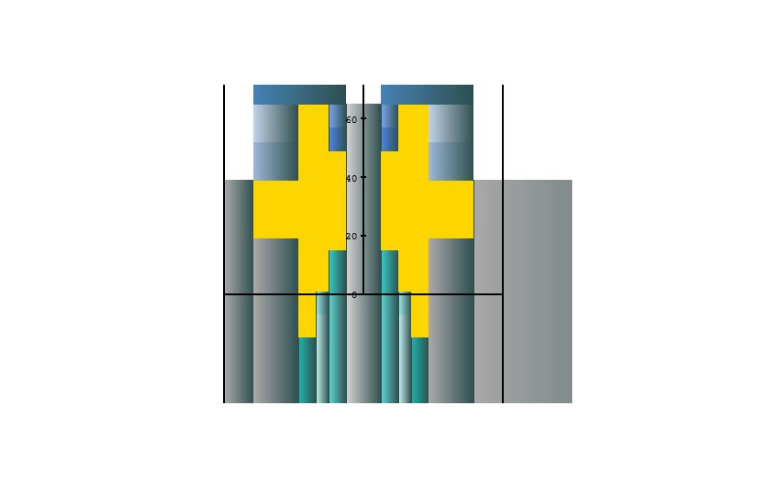

Step 3: Compact

The powder columns are axially pressed (two opposing directions) to densify the column at the same rate. The size and density of the green part is established at this compaction position.

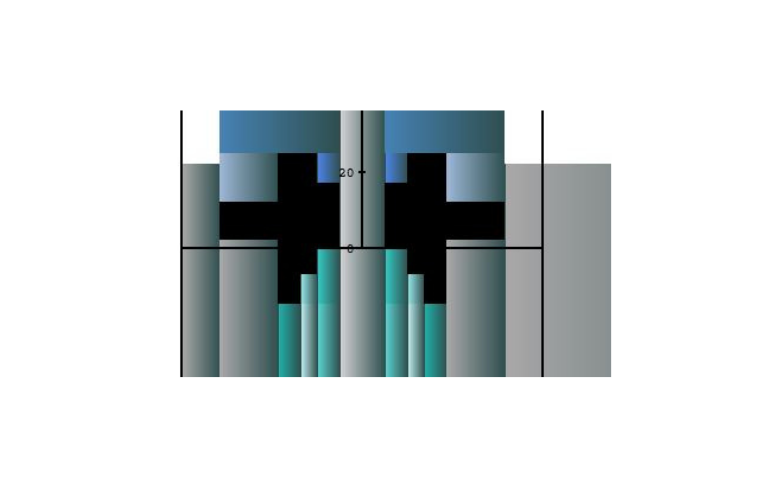

The Compaction Process

The compaction of components is a metalworking process using powder metal to manufacture powder metal parts that range from simple to high complexity levels.

During the compaction process, powder fills the die cavity and is transferred in columns to be even compacted and ejected as a 'green' part that is ready for sintering.

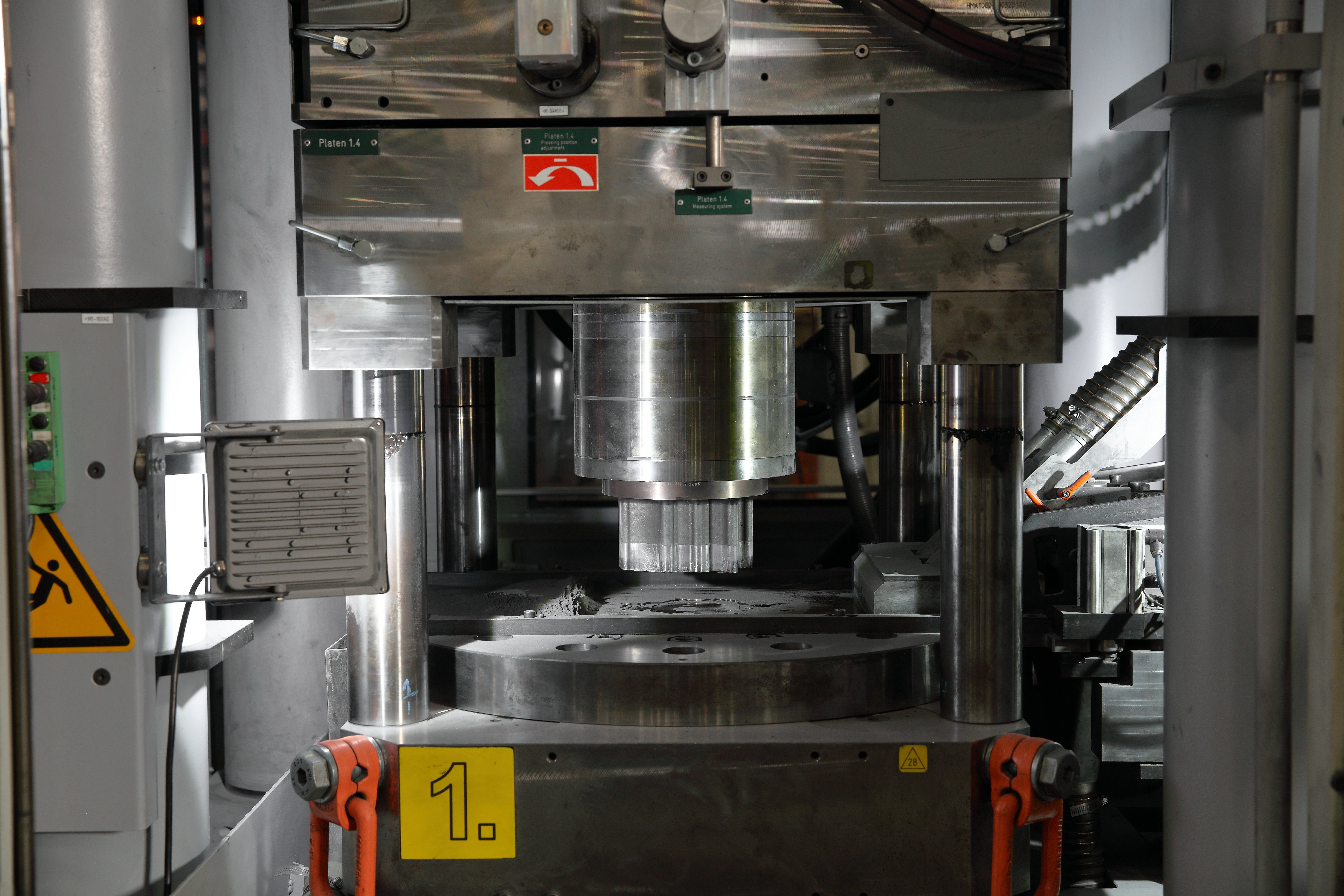

With an internal automation team, DSB Technologies has implemented automated systems throughout the compaction process - like hands-free green part handling before sintering - to improve quality performance and increase operational efficiency.

Advancing the Compaction Process

DSB Technologies has been compacting powder metal components for more than 50 years, delivering innovative advanced designs for our customers and their applications.

With recent additions in new computer numerical control (CNC) presses to its existing compaction portfolio, DSB Technologies manufactures highly complex metal parts - enabling customers to meet new design challenges with economical solutions for high volume production.

CNC Press Technology Characteristics & Benefits

Efficient Medium-High Volume Production

DSB Technologies is equipped to handle medium to high volumes of production with our extensive pressing and sintering capacity.

Design Flexibility

Undercut or cross hole features are possible with CNC press technology. DSB Technologies also offers dual material components to eliminate assemblies.

Medium Complexity Parts

Simple discs or ID and OD features can be produced with mechanical presses, while undercut features are possible with CNC press technology. Parts with 4 to 6 levels can be produced on DSB's CNC presses up to 800T.

In-House Operations

DSB Technologies' 250,000 sq ft facility is equipped with hands-free robotic handling during pre- and post-sintering operations, in addition to secondary CNC stations.

Press & Sinter Technology Resources

DSB Technologies is your end-to-end Manufacturing Partner with:

Compaction & Press Technology FAQ

What is compacting in powder metallurgy?

What is compacting in powder metallurgy?

In powder metallurgy, compacting refers to the process of applying pressure to metal powders to shape them into a desired form. This is typically done using a mechanical press or hydraulic press.

What is compaction, and how does it differ from other forming processes?

What is compaction, and how does it differ from other forming processes?

Compaction is a forming process used in metal binder jetting to compress metal powder particles together to form a part. In metal binder jetting, after the metal powder is deposited layer by layer and binder is selectively deposited to bind the particles, compaction is applied to ensure the particles are tightly packed before the part is sintered.

How does compaction technology contribute to the metal binder jetting process?

How does compaction technology contribute to the metal binder jetting process?

Compaction technology plays a crucial role in the metal binder jetting process by improving the density, mechanical properties, and overall quality of the green parts produced. Here's how compaction technology contributes to the metal binder jetting process: increase density, improve mechanical properties, enhanced dimensional accuracy, uniform material distribution, optimized surface finish, enhanced sinterability

How does CNC press technology work for metal part fabrication?

How does CNC press technology work for metal part fabrication?

CNC press technology offers a highly controlled and efficient method for fabricating metal parts with complex shapes and precise dimensions. Its automation capabilities, combined with digital control and monitoring, make it a versatile solution for a wide range of metal fabrication applications across various industries.

What types of metal parts can be fabricated using CNC press technology?

What types of metal parts can be fabricated using CNC press technology?

CNC press technology offers versatility and precision in fabricating a wide range of metal parts with varying complexities, sizes, and applications across industries such as automotive, aerospace, electronics, construction, and consumer goods.

What are the benefits of CNC press technology?

What are the benefits of CNC press technology?

Benefits include design flexibility, efficient medium-high volume production, and the ability to produce complex parts.

What materials can be used in CNC presses?

What materials can be used in CNC presses?

Materials include iron alloys, stainless steels, and controlled porosity materials.

What is CNC press technology?

What is CNC press technology?

CNC press technology uses computer numerical control to press powder metal parts with high precision and repeatability.

What is the typical production volume for CNC presses?

What is the typical production volume for CNC presses?

CNC presses handle medium to high volumes of production.

What design features are possible with CNC press technology?

What design features are possible with CNC press technology?

Undercut or cross hole features and dual material components are possible.